Conceived and designed as a moderately priced dock and material handling solution, the 6200 Series service garage doors feature full-sized, 24-gauge slats and incorporate structural steel guides, full-sized head plates, structural hood, self-aligning drive bearings, and quick-release guides. The commercial design features accrue into a true feature-packed, value-added package. The steel components of this door are 100% recyclable post-consumer, making them the right choice for green sustainable buildings and LEED projects.

FEATURES

- Slat Profile: Standard sized commercial 2-3/4” interlocking flat slats in hot-dipped galvanized 24-gauge steel

- Operation: Manual push-up, chain hoist (standard) or motor operation

- Max Size – 12′ x 14’4″ (contact customer service for larger sizes)

- Colors: Pre-painted in gray or white or optional stock RAL powder-coat option in 188 colors

- Half-hexagonal formed hoods deliver superior structural rigidity and aesthetic appeal

- Value is enhanced by building realtime performance expectations into time proven, reduced cost design

- Options and accessories available

CURTAIN

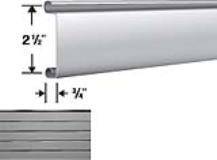

SLAT PROFILE:

- Flat Slat (FS) cover 2-1/2” high by 3/4” deep

ENDLOCKS & WINDLOCKS:

- Malleable, zinc-placted cast iron endlocks and windlocks maintain curtain alignment and increase windload capacity. Galvanized malleable cast endlocks are fastened to every other slat. Windlocks are added as dictated by door size & windload requirement.

- Windload: Designed to withstand a minimum of 20 lbs psf (per sq feet) of windload to an amount that prevents curtain per square foot of windload deflection to prevent buckling or being blown out of the guides.

GAUGE:

- 24 gauge interlocking galvanized steel

FINISH:

- White or Gray

- Optional: Stock RAL powder-coat option in 188 colors

- Slats are hot-dipped galvanized per ASTM A653 A with baked on epoxy primer and polyester finish coat available

VISION PANELS:

- 5″ x 1-1/8″

MOUNTING OPTIONS

MOUNTING OPTIONS:

- Face Mount (E or Z) or Jamb Mount

- Mount to Steel, Wood or Masonry Jambs

GUIDES:

- Fabricated from three (minimum 1/8” structural steel angles bolted together to form guide channel.

- Guide angles include curtain stops & flared guides

- Hot-dipped or cold sprayed galvanized guides (optional)

HEADPLATES:

- Fabricated from minimum 1/8” steel plate.

- Drive side of barrel to be provided with precision sealed ball bearing in cast iron housing

OPERATION

Manual Push-up, Chain-hoist (standard)

SPRINGS:

- Spring tension assembly within barrel by precision ball bearings.

- Assembly designed for 10,000 cycle life springs (Standard). Higher cycles optional

MOTOR OPERATION:

- Rolling Doors are also available with Motor operation.

- Refer to the motor operator area chart to select operator type based on dimensions and gauge

- Choose between wall mount or front of headplate mount. Use the charts to determine headroom, sideroom and backroom clearance requirements.

OPTIONAL ACCESSORIES

HOOD:

- Fabricated from minimum 24-gauge galvanized steel sheet shaped to fit within the headplates. Intermediate hood support(s) furnished as required.

LOCKING:

- Manual push-up doors furnished with interior slide bolt locks with padlock provision standard.

- Chain hoist doors operated doors furnished with chain hoist keeper suitable for padlocking.