Rolling service doors to meet your most demanding and rigorous applications

The Wayne Dalton Model 800 rolling service door is designed to meet the tough requirements of virtually any commercial or industrial application.

The Model 800 offers flexibility in substrate materials with choices of galvanized or prime steel, stainless steel, or aluminum.

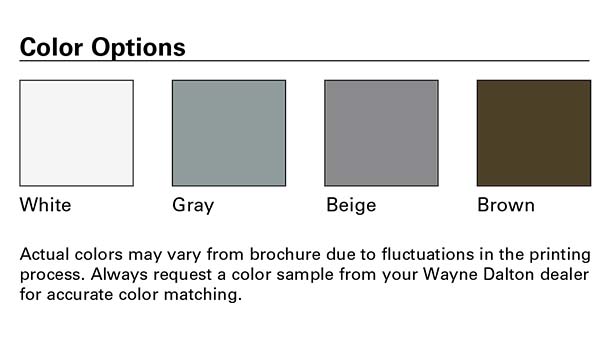

Color options range from our standard five factory finish colors to a full range of 197 RAL powder coat choices.

Features

- Standard Max Width 40′

- Standard Max Height 40′

- Steel, aluminum or stainless steel construction

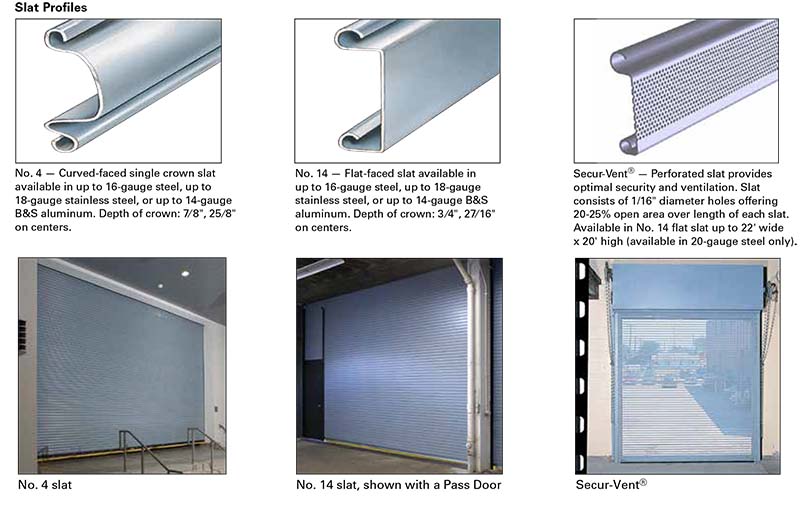

- Heavy-Duty 3″ flat or curved slats

- Wind load 20 PSF standard; options up to 55 PSF

Options & Accessories:

- Secur-Vent® perforated slats

- Vision slat

- Open fenestration slat

- Over-sized Titan™ for large door application such as hangar door (up to 70’ wide)

- High Wind load

- Articulating Windlocks for Operational Windload

- Brush Seal for Curtain, Lintel Brush, and Hood Baffle

- Manual Chain Hoist

- Motor Operator

- Bottom Bar Sensing Edges

- Anti-Drop Devices (including Wayne Dalton’s Proprietary DSD – Drop Stop Device, and Brake Devices)

- Exhaust Ports

- Sloping Bottom Bars

- Mullions

- Optional powder coat finish

- Pass Door

Materials & Construction

Wayne Dalton’s Model 800 rolling service doors are composed of curved or flat-faced slats that provide a natural water-shed, helping to reduce corrosion. The slats are designed with free-acting interlocking joints that permit easy articulation when the door coils.

The Model 800 features a strong double-angle bottom bar that reinforces the lower edge of the curtain against wind pressure and permits varied lock, astragal, and safety edge options. This bottom bar is designed for easy installation and does not require fasteners protruding into the guide openings, so the bottom bar does not interfere with door operation.

Counterbalance assembly consists of a spring barrel which serves as a load-carrying beam. It encases the counterbalance mechanism and provides the axis around which the curtain coils. (Deflection is limited to 0.033″ per lineal foot of span.) If required, barrel rings of malleable iron or stamped steel may be provided to assure proper counterbalance. Oil-tempered, torsion-type counterbalance springs are wound from heat-treated steel, providing accuracy in balancing the door. Barrel plugs connect ends of springs to barrel and tension rod. Tension rod of steel shafting holds fixed ends of springs and carries torsion load of spring counterbalance.

Spring tension adjusting wheel is normally mounted outside the bracket on end of tension rod. Inside adjusting wheel for tight side-room applications is available in limited sizes.

The hood covers the curtain coil and counterbalance mechanism. Slat hoods are available on gray, brown, beige, and white doors.

*Wayne Dalton uses a calculated door section R-Value for insulated doors.